Developed years ago to speed up work rates, pulse-width modulation (PWM) systems are now used to improve accuracy and slash chemical costs.

PWM spraying includes:

- Individual nozzle control

- Overlap and turn compensation

- Quick, real- time flow rate changes while minimally impacting droplet size

Currently it is common to set up the machine in a way that all plants get at least the desired rate. Application rate and tank concentration are set according to the more extreme case. This results in applying too much on most areas in the field, while there are others which do not get enough. As a result of the current state of technology, more inputs are needed and the distribution over the field is not even. Agrifac decided to deal with this shortcoming in spray technology by developing its own PWM spraying system: StrictSprayPlus.

Farmers need the guarantee that a solution is sprayed with the desired rate at the right place, so the solution can work, protect, and feed the right plants at the right place. With StrictSprayPlus you can and will apply perfect amounts everywhere at all times. StrictSprayPlus has three characteristics which help it to apply the exact amounts everywhere.

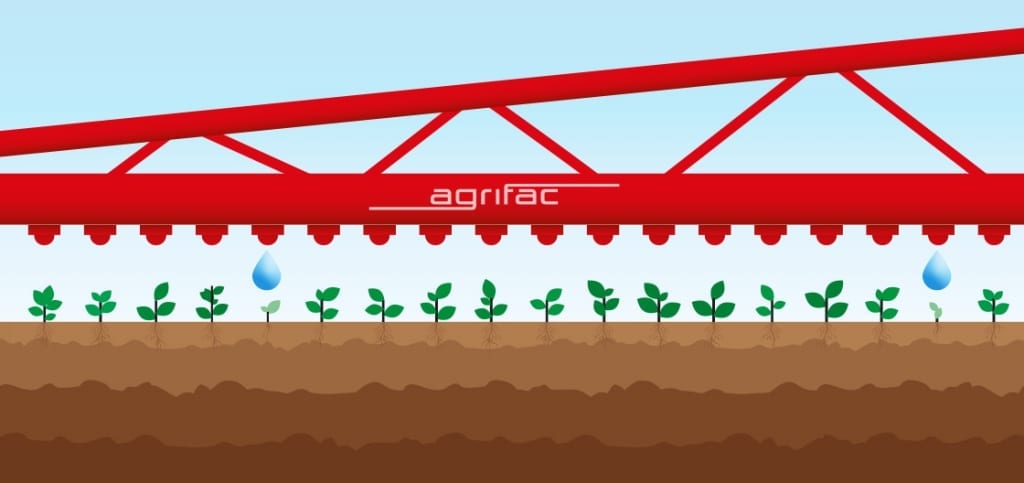

1. Single nozzle sections.

To prevent overlap and overdosing to the maximum, every nozzle can be switched on/off individually.

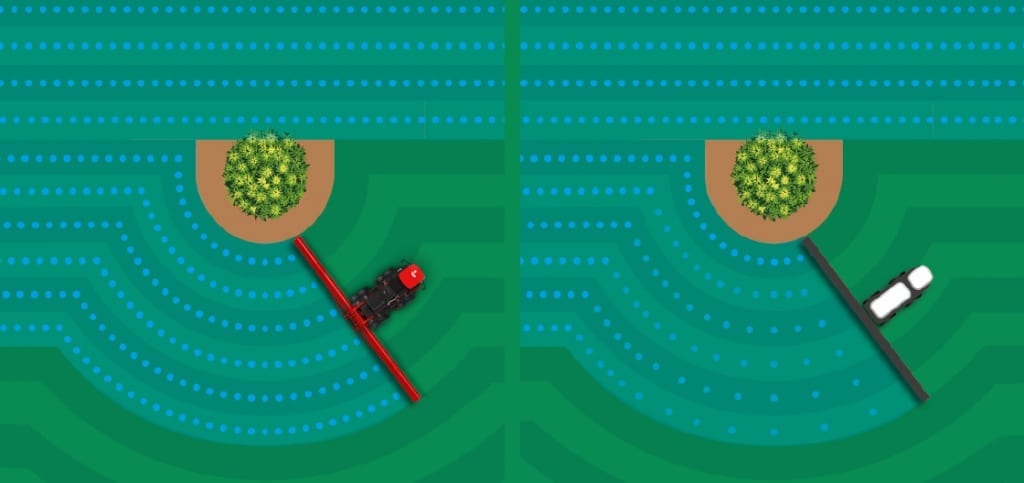

2. Turn compensation.

When making a turn while spraying, different nozzles move at different speeds (the outside turn is a longer path, than the inside turn). In order to spray consistently at the same rate, faster moving nozzles need to spray more, and slower moving nozzles need to spray less. StrictSprayPlus is the first system truly compensating for this, spraying 100% coverage everywhere.

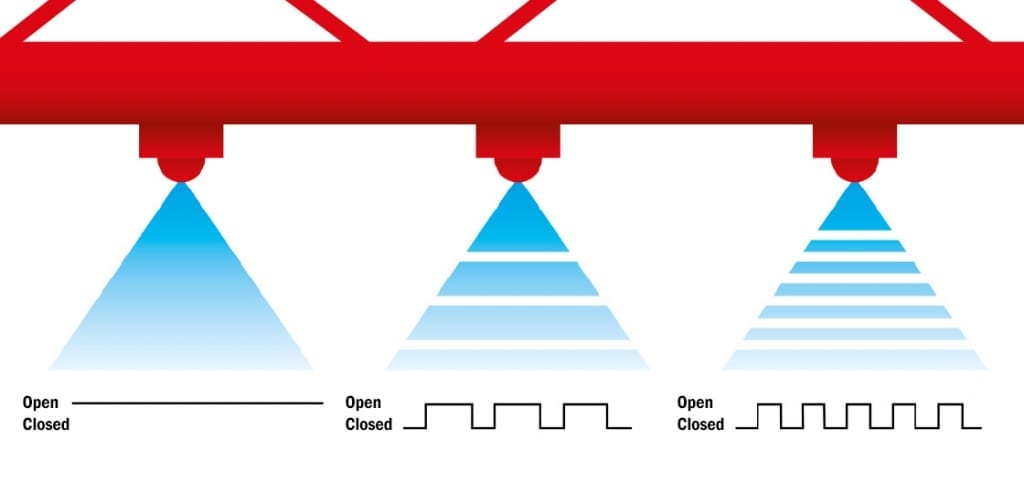

3. Pressure independent rate control.

Regular rate control is achieved by changing the water pressure. However, changing the pressure does not only change the flow rate through each nozzle, but also changes the spray pattern and droplet size. StrictSprayPlus does not need to change the spray pressure to change the flow rate, therefore the spray pattern and droplet size stay the same, regardless of the flow.

Control per nozzle

In order to achieve all this, StrictSprayPlus calculates the speed and required spraying rate for every nozzle. These values are used to determine how much every single nozzle needs to spray. The flow is controlled by changing the time the fast (up to 100 times a second) switching nozzle body is open and closed. By varying the frequency and the open/close ratio the final rate per nozzle is established. Due to the ability to change the opening and closing time individually, the number of switches per second is as low as possible, but as high as necessary. This ensures the spray pattern is always accurate, while the lifespan of the valves is extended.