Hryhoriy Suprun

*This article previously appeared in the Ukrainian Farmer – August 2021.

Spraying should be only high-qualitatively

The owner of Niva 2008 LLC, Hryhoriy Suprun is convinced that the sprayer should be only the best – this is the only way to guarantee the effectiveness of significant investments in crop protection.

Modern spraying technologies have advanced far over the last 10 years. However, only a few manufacturers offer truly revolutionary things that can significantly expand the capabilities of the sprayer. The owner of Niva 2008 LLC, Hryhoriy Suprun had to see from his own experience what can be obtained from one of the best self-propelled sprayers on the market. Since 2017, they have been using the Agrifac Condor model with the HTA system here, and they see only positive moments in this.

Our first experience with the Agrifac Condor

The first acquaintance with the Agrifac Condor sprayer took place when this machine was rented from the dealer company Concord for urgent fungicide treatment of sunflower. The first impression of the sprayer was the best. The rapid change in ground clearance, high quality spraying and low operating costs simply impressed. The machine worked in the fields of the farm during the season, and this made it possible to compare its productivity with the productivity of trailed sprayers, which were previously used on the farm. As part of planning the further development of the farm, it was decided to purchase its own self-propelled sprayer.

At the Agritechnica exhibition, it was decided that it would be an Agrifac machine. Self-propelled sprayers of several other manufacturers were considered, but one lacked spraying technology, the other lacked ease of operation. At the end, they agreed with the dealer that they would come to the Agrifac factory together and pick up the necessary complete set. They carefully approached this issue, and the sprayer really turned out successful. Additional options include a set of LED lighting for safe operation at night, as well as an additional carbon filter, which guarantees the operator protection from chemicals.

Operator is completly protected

As a result, when the machine appeared at the plant and the operators saw the conditions under which they would work, the attitude to spraying immediately changed. If before everyone refused to work on spraying due to health risks and unpleasant odors, with the advent of the Agrifac sprayer it became clear that the operator is completely protected from the negative effects of chemicals. In addition, the work was organized in such a way that the operator did not leave the cabin at all, and a separate team was engaged in refueling.

Gregory Suprun noted that the variable clearance allows you to work from the initial stages of plant vegetation and up to the desiccation of sunflower. By the way, the quality of desiccation was much better than with the use of aircraft.

HTA system for working in different weather conditions

For 5 seasons the sprayer has shown itself as reliable and trouble-free. Of course, there were questions due to ignorance of technology, sometimes there were breakdowns, but nothing critical that could stop the work in the field did not happen. Service issues were resolved with dealers, and even when difficulties arose, they were still resolved.

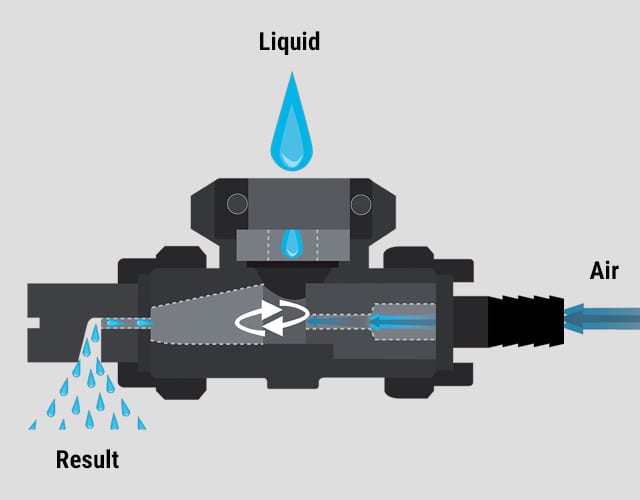

Of course, the sprayer was equipped with the HTA system, which allows you to work at any time when the wind speed reaches 10-12 m/s or more. Conventional nozzles cannot be operated under such conditions, while the HTA system can be used to increase the droplet size so that the wind does not affect its trajectory and the required coating (covering) quality of the target surfaces is ensured.

When they began to assess the quality of the machine, they tried to reduce the flow rate to 100 and even to 50 l / ha. As a result, it was concluded that soil herbicides can be applied at the rate of 175 l / ha, and insurance herbicides – at the rate of 125-150 l / ha. Tried to use the lower rate but reduces the productivity of the machine. For such work the more powerful water pump is required, namely this sprayer is equipped with the standard. Hryhoriy Suprun noted that for the new sprayer will definitely take a more productive pump into account.

HTA system

Spraying with HighTechAir

Individual nozzle control in the boom

To reduce the consumption of the working solution, the sprayer is equipped with individual nozzle control and the liquid circulation system in the boom. This avoids gaps and overlaps, as well as improves the situation with protection on reversible lanes. The circulation of the liquid in the boom ensures the homogeneity of the solution even when using powdered PPT. There are no questions about the concentration of the solution or the uniformity of spraying across the width of the boom.

According to the owner of the farm, he has not yet seen a better quality of spraying than in Agrifac Condor machines with the HTA system. Doubts about the purchase of this system disappeared after the visit to the Dutch farmer and he saw that the sprayer was operating in fairly windy weather. A large wind generator was actively working near the farm, ie the wind speed was quite high. However, this did not stop spraying.

“Today, the cost of PPT has risen to such a level that farmers can’t risk protecting and spraying the fields in vain. If you have already spent money on the crop protection, it must be made according to the technological map, taking into account the phase of plant vegetation, temperature and humidity. For example, last year 80-90% of the sprayer’s operating time was at night, when the temperature dropped to an acceptable level. And during the day and in the evening, when the temperature was at the level of 30-35 degrees, no one sprayed, despite the presence of such the high-tech machine. As for the HTA system, I think that working without it is like working without navigation. It frees our hands and greatly expands the “window” of favorable weather for plant protection.

Hryhoriy Suprun, the owner of Niva 2008 LLC

“The LED lighting system allows the operator to see the entire processing lane, which improves safety. The steering is autopilot, the height of the boom is also maintained automatically. We do not have large slopes, but there are still irregularities, so this feature is useful for operating from a given height.”

When the owner of the farm went to the factory to order a sprayer, he was advised to take a wider boom so that he could drive at a lower speed without losing productivity. However, they decided not to take risks and not to take a 45-meter boom and chose a 36-meter one. The sprayer operates at a speed of 9-12 km / h. For some it is very slow, but according to the owner of the farm – “to fly” on fields at a speed of 25 km / h is rather risky because of existence of various obstacles.

In addition, there are cases when the rains wash away the hills or animals can dig a hole in the technological track, and the operator has to brake sharply, which in turn can lead to damage or breakage of the boom. Also, rapid movement provokes the formation of a dust cloud behind the machine, which greatly impairs the effectiveness of the PPT in the area of the technological track. Therefore, they do not chase the speed here, and have time to spray 500 hectares daily or 250-350 hectares at night. This is enough for the needs of the farm.

The company

Niva 2008 LLC operates in the Chernihiv region and cultivates about 3,500 hectares of land. In addition to crop production, there is a powerful livestock unit, so about 1,000 hectares are under fodder crop rotation. Other areas are used for commercial crop production. In general, maize is grown here – almost 2000 hectares, sunflower occupies up to 500 hectares, 250-350 hectares of rapeseed and soybeans. Winter wheat occupies 400-500 hectares, barley – 200-300 hectares, alfalfa – 250 hectares and few hundred hectares under sugar beets.

The owner considers the technological sides of the sprayer as an indisputable advantage. The high quality of spraying makes it possible to reduce the number of treatments, as it turns out, you can reduce the concentration of the working solution, and thus save money without losing efficiency.

Hryhoriy Suprun is convinced that the system of spot spraying of certain types of weeds, which is already being actively tested, significantly distinguishes Condor sprayers from machines from other manufacturers. Now more and more farmers are faced with Syrian silkweed (Asclepias syriaca), field bindweed (Convolvulus arvensis) and ragweed (Ambrosia artemisiifolia L.). These weeds appear much later than the main crops and post-emergence herbicide treatments. At this time, the air temperature rises, which significantly complicates the fight against weeds. Additional continuous treatment with herbicides in any case will cause significant stress on crops and slow down their vegetation, which will inevitably affect yields. If you work locally, you can get huge savings on PPT and water logistics, as well as avoid the stress of most crops in the field.

Learn More about the Agrifac Condor

Condor Endurance II

Condor Endurance II

- Built for maximal capacity and speed

- J-booms available up to 55 metres

- 8000 litre tank

- Red dot Award winning 2019

More user experiences

Hryhoriy Suprun

Since 2017, they have been using the Agrifac Condor model with the HTA system here,

Horst Brammer

My name is Horst Brammer and I am the operations manager of Kartoffelhof Nüssau GmbH, a part of the Heilmann AG. Here in Schleswig-Holstein we grow on 370 hectares table potatoes.

Rory Vermeesch, Mount Madden WA

The ability to impact the least amount of crop as possible while spraying was a huge factor in buying the Agrifac.